Mechatronics Engineering is a branch of engineering that deals with the design of mechanical and electrical parts of a mechanical system. It is implemented in almost every industry, medical services, outer space research, and all the tools that ease our daily tasks. This engineering sub-branch is wide-ranged and typically refers to the integration of telecommunications, mechanical, and systems engineering, which generally use micro control systems.

In the mechatronics field of engineering, a "control system" comprises a mechanical component set that is interconnected or joint in a format that may regulate, guide, or control the system or the other systems. Hydraulic, Electrical, mechanical, thermal, pneumatic, or biochemical components are examples of physical elements of a control system.

Computer engineers collaborate with animators in the film business to generate special effects. This "morphing" technique makes computer images appear realistic. - nspe.org

It can be considered a cross-disciplinary unit as it captures elements from mechanical and electrical engineering. Let’s learn more about the modelling and control of mechatronic systems through this blog.

What are the principles of open-loop and closed-loop control systems?

The car's direction is managed through the wheel position, which manually manipulates the gear stick. A control system for a car is comprised of the steering wheel, rear driveshaft, connections, and wheel. A steering wheel location is a source in this system, while the wheel alignment is the control sample or output.

There are mainly two types of control systems, which are:

Open-loop Control Systems

Fundamentally the result of an open-loop control system should not be implemented as a variable to operate the system. In layman's language, open-loop systems do not limit the program's input as per the current output. It is an important concept in the control of mechatronic systems.

An amplifier is another good example of an open-looped system, the main features of the process are an accelerator and a control unit. The accelerator takes a limited input and enhances it sufficiently to trigger the control loop to do the required task.

When considering an automated toaster, for instance. Whenever the toaster is switched on, the heating system in the toaster heats up the bread for a period, and then it automatically switches off and ejects the toast. Still, there is a lack of feedback or statistics on if the bread is properly cooked.

Closed-loop Control Systems

A feedback control system is used to ensure the proper functioning of a closed-loop system. In feedback control or a closed-loop system, the controller observes what happens at the output terminals and directs the plant to produce the desired output. It is a good example of modelling and control of mechatronic systems.

Several examples, such as industrial cooling controllers and car automatic steering systems, have previously been explored in prior subjects. A further illustration of a "closed-loop control system" is a room heating/cooling system. A thermometer (input) requests heat.

The heating coil of the steering system - output - produces and transfers heat. When the thermostat receives much of the energy, this results in the "feedback" bringing the indoor room temperature to the present, which results in turning down the system until more heat is needed.

The Ferris wheel was first invented in 1893 by George W. Ferris. It provided access to high-quality steel towers, and the 45-foot spindle was the biggest piece of steel ever built. - Wikipedia

Technical writing can be challenging, and the technical lexicons and the structuring are difficult to grasp. You might face issues finding adequate resource material and need someone to do the final proofreading. Fill out the enrolment form to get engineering assignment help from experienced academic writers at affordable prices.

What is the impact of performance controllers in the industrial field?

"Control Performance Management" in Industrial Automation offers a systematic and self-functioning treatment of a group of concepts and techniques that are becoming increasingly important in the identification and resolution of issues with control loops, which are essential to preserving service quality, device performance, and the durability of energy and materials used in the manufacturing systems.

The monograph covers all areas of "control performance management " or "CPM", through the control-loop evaluation ("minimum-variance-control-based" and advanced approaches) through control loop identification and diagnostics (oscillations, sensor failures) to control optimisation (re-designing the elements of the loop, maintenance, controller re-tuning) in the control of mechatronic systems.

Australia has five science and engineering universities listed among the global top fifty. - Australia Government

It contributes to the sector's growth and use of self-contained and automated approaches. Furthermore, several CPM tools that will go much beyond existing CPM products have been created as part of this study. "Control Performance Management" is helpful in Industrial Automation because:

- Provides a thorough examination of control performance evaluation techniques

- Creates processes and tactics for detecting and diagnosing the underlying reasons for poor performance in complicated control loops

- It helps cover essential issues in the assessment of diagnostic procedures in the control performance unit.

- New approaches can be generated to develop new processes for ensuring the optimal control loop performance per the outcomes of the performance stage.

- Some examples of industries that use performance controllers are - mining, mineral/metal extraction, construction, chemicals/pharmaceuticals, and paper and pulp processing.

The advanced industrial control loop is based on the objective of technology transformation of technology in a controlled engineering environment. The fast-paced development of the control loop technology will impact all areas of industry that work within a control discipline/environment. Yet, this technology presents a plethora of prospects with the extended exposition of industrial control.

What Are the Applications Modelling and control of mechatronic systems?

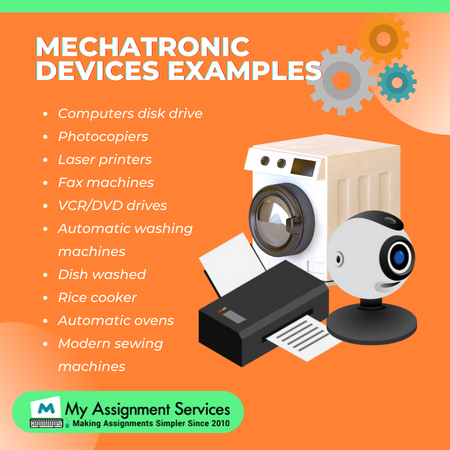

The application of digital control and electro-mechanic systems or “mechatronics” is a much-needed response to the industries evolving with digitisation. The increased demand for highly-efficient systems and technology requires modelling and control through mechatronic systems. The most efficient digital control form is the one that is tie-driven and integrates event-control characteristics in a single scheme.

Moreover, the design-control unit's current engineering trends and requirements offer leeway for incorporating separate discrete-time and event systems. The Mechatronic control systems, along with the model-oriented design and implementation, revisit the concept of automation via practical methodology in control loops. An entire integrated control system represents a unique system-integration form.

Did you know that Australia has over fifty accredited engineering programs?

Furthermore, mechatronic engineering and industrial automation are a sub-filed in engineering disciplines, including the revolutionary hybrid algorithm for modelling, analysis, and control of mechatronic systems Implementation. Real-world design issues and case studies in automating assist readers in putting theory into practice, whether creating single units or large-scale industrial networks.

Report writing can get challenging as your theme may not allow you to make it as informative and interactive as you want; inadequate research materials might be the reason. You can get free academic resources from our extensive digital library. Get professional academic writers' assignment help at affordable prices; enrol today to get started.

Related Study Materials

Our Experts can answer your Assignment questions instantly.

Ask Question0 Comment

Get It Done! Today

1,212,718Orders

4.9/5Rating

5,063Experts

Loved reading this Blog? Share your valuable thoughts in the comment section.

Add comment