- University : University of Salford My Assignment Services is not sponsored or endorsed by this college or university.

- Subject Name : Management

Executive Summary

Walmart has the best logistic management and supply chain management, that helps the organization to reduce the storage and transportation cost. The report has critically discussed the procurement functions of Walmart. In the report, strategies to improve the procurement function of the organization are briefly discussed. The strategies include partnership with suppliers and use of computers for supply chain management. By compensating external turbulences in the market the supply chain management can be made more efficient. Technology has played a vital role in improving the supply chain of the organization. The sourcing and outsourcing strategy include technology, strategic vendor partnership, and cross-docking. Moreover, the report has provided procurement strategies, supply risk tactics, and sustainable procurement to improve the procurement function.

Table of Contents

Walmart's Procurement function 5

Strategic Sourcing and Outsourcing 5

Strategic Vendor Partnership 6

Integrated supply chain management 8

Highly responsive supply chain 8

Supply Risk management tactics 9

Walmart Sustainable Procurement 9

Sustainability Measures development 11

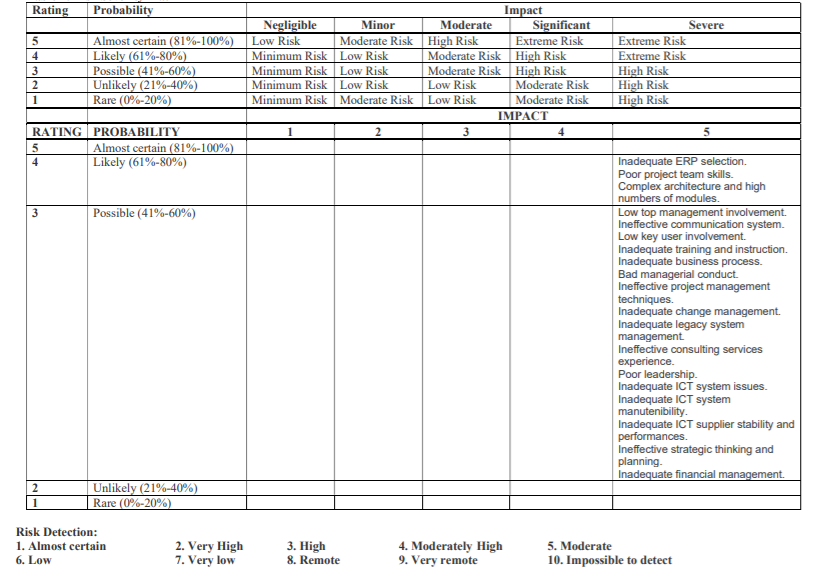

Risk Matrix and Risk Register 16

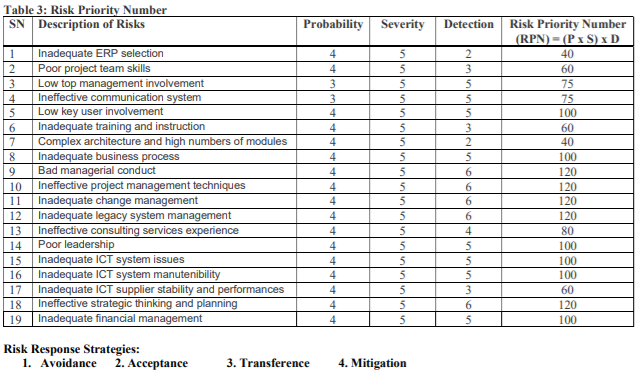

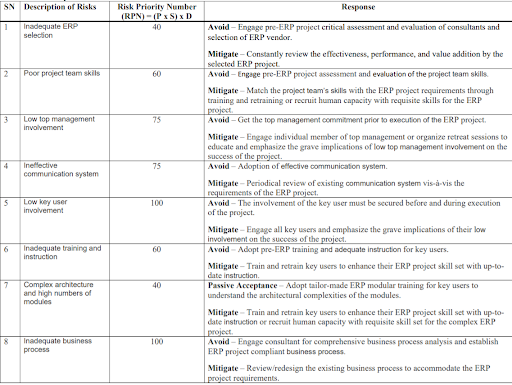

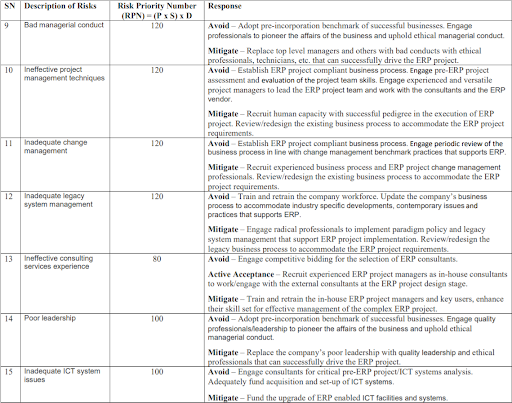

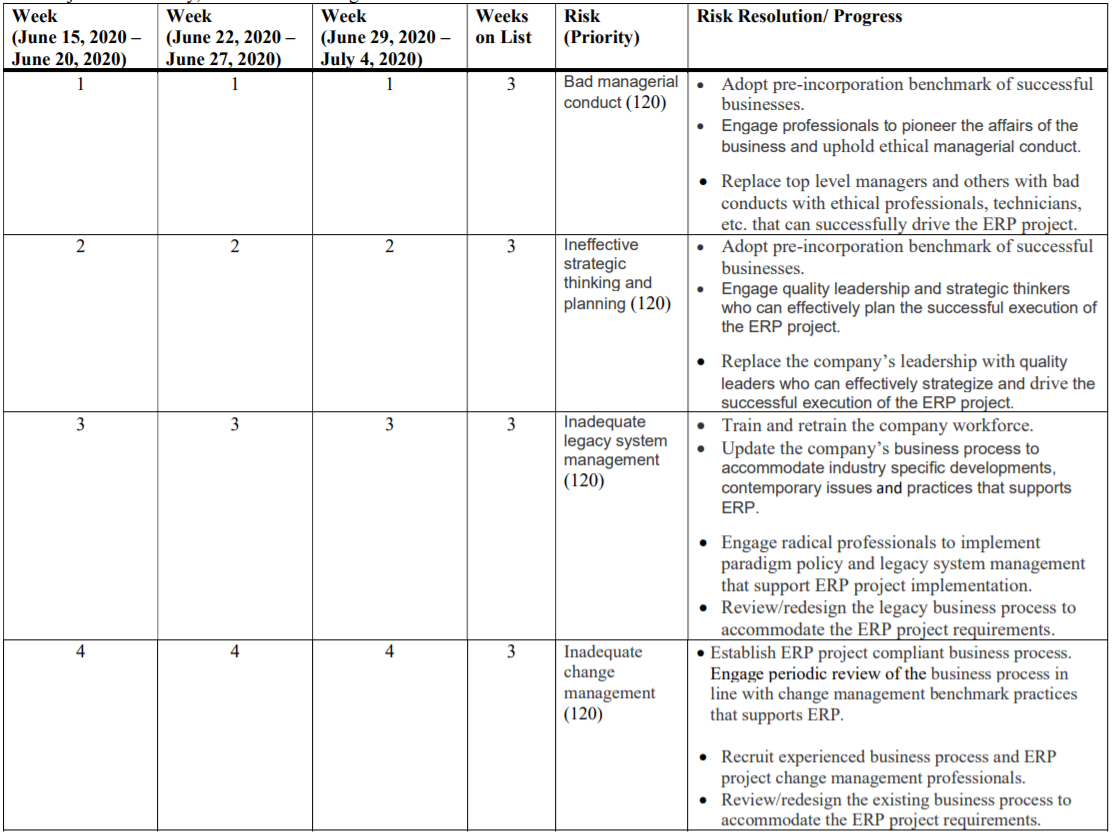

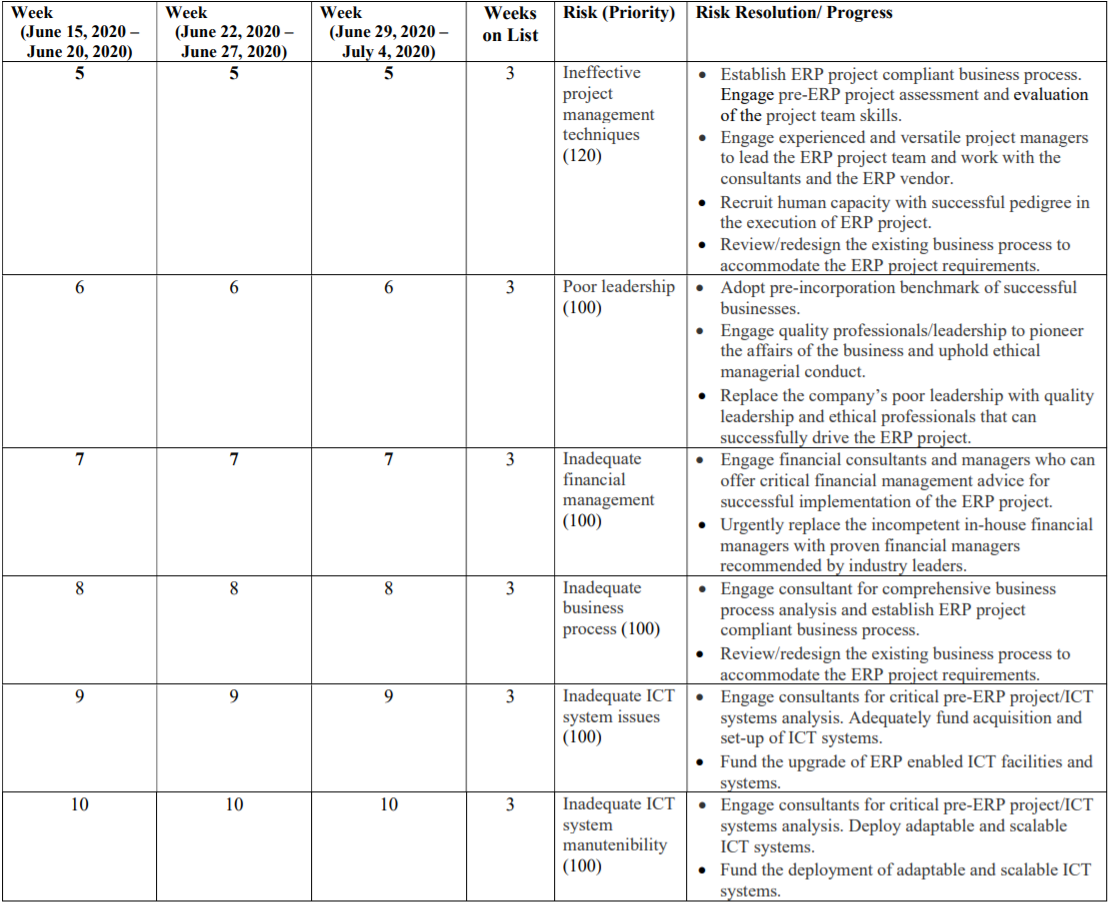

Top 10 ERP Project Risk List 22

Introduction

The aim of the report is to critically examine the Procurement function of an organization. The organization selected for the report is Walmart. The report will discuss the strategies to improve the procurement function of the organization by compensating external turbulences in the market. To improve the procurement function, the report will focus on procurement strategy, strategic sourcing and outsourcing, supply risk, and sustainable procurement. Walmart is an American retail corporation headquartered at Bentonville, the United States that operates a chain of the grocery store, department stores, and hypermarkets (Wells and Ellsworth 2016). The procurement function of Walmart will be analyzed in the report as procurement operation within the organization can help in taking competitive advantage by reducing waste in the value chain.

Walmart's Procurement function

As per Theron and Dowden (2017), the organization wants to offer customers with goods and services at the best price by reducing the purchasing cost. Whereas according to Grangier, Gendreau, Lehuédé and Rousseau (2017), the organization is reducing its cost by reducing the cost supply chain through innovative strategies. The organization directly deals with manufacturers for goods and services by avoiding all the intermediates. The organization only finalize its product deal when it is fully convincing and confident that the product which they are purchasing is not available in less price at other company or market. The organization takes a lot of time in confirming their cost structure and for this, Walmart spends time with its venders in meeting them (Theron and Dowden 2017)). The process of purchasing and estimating cost is transparent which helps the organization to cut down the cost. In addition, manufacturers are also doing their best in cutting the cost. Walmart uses EDI for its procurement. The suppliers are connected to the organization through computers where EDI enables them to download the purchase order. The information of the store to store sales are also provided to the suppliers through EDI along with the product sales information. This helps the supplier to ship the goods that are required at various stores to the distribution centers of Walmart (Cleary and McLarney 2019).

Strategic Sourcing and Outsourcing

According to Chang and Hu (2020), Walmart is one of the biggest organization which deals in providing grocery items in the United States. The organization had gone a big change in its sourcing strategy. The organization has saved a lot of dollars by combining its functions of procurement globally and reducing/eliminating the intermediaries in the sourcing process. The organization was highly dependent on the intermediaries till 2010, for its global sourcing (sourcing of goods and services from the global market to geopolitical boundaries) activities and due to which the organization was unable to gain that much profit as it requires (Barber 2018). The intermediaries were only about to bring around 30 per cent of profit from the supplier. In addition, the organization's operational model was highly decentralized due to this dependency in almost all countries where the company has its stores. However, now the company directly deals with its manufacturers and brings almost 80 per cent of goods. The company has changed its strategic sourcing and outsourcing to increase its profit. Due to this change, the organization has eliminated the intermediaries and their introduced markup (5 to 15 per cent)(Barber 2018). As a result of which, the organization has reduced the cost leading as well as it has improved the efficiency of the supply chain process. Some of the strategies used for sourcing and outsourcing are as follows:

Strategic Vendor Partnership

According to Cleary and McLarney (2019), the organization selected those suppliers who were capable of providing the goods at the best prices as well as meeting the demand at the same time. The organization has used a strategy of offering suppliers with high volume purchase and long term relationships. Walmart developed a strategic relationship with its suppliers in exchange for the lowest price possible for the goods. Moreover, the organization has developed a network through which they were connected to top their suppliers. As a result of good communication and relationship, the organization was able to enhance its material flow as well as was able to maintain the supply chain efficiently. Collaboration with the vendors works as a key to success for the organization (Cleary and McLarney 2019).

Cross Docking

According to Grangier, Gendreau, Lehuédé and Rousseau (2017), a key inventory tactic called cross-docking is used by the organization for its sourcing strategy. Walmart directly transfers the products from inbound trucks to outbound trucks. Cross-docking has resulted in reducing or saving of the storage cost for the organization. This is carried out very effectively. The suppliers of Walmart delivers the product at the organization’s distribution centers, where the product is cross-docked with the help of inbound trucks and outbound trucks and then the trucks deliver the product to the stores of Walmart wherever there is a requirement. This process eliminates inefficiency and lowers the cost of inventory transportation (Grangier, Gendreau, Lehuédé and Rousseau 2017). This results in company saving which is further transferred to the customers in the form of competitive prices. Besides this, the organization has nearly 160 distribution centers which have enabled the organization to create a cost-effective distribution network, located within the range of 130 miles from the stores where the organization supplies the goods (Grangier, Gendreau, Lehuédé and Rousseau 2017). Moreover, Walmart's regional distribution centers are located in such places where the labor cost and transportation cost is lower. This process has made the cross-docking easier for the organization.

Technology

According to Heller (2017), the organization has taken the help of technology to track its inventory and restock the shelves with required goods. Walmart's supply chain is incomplete without the use of technology. Technology has played a vital role in improving the supply chain of the organization. Technology has enabled the organization to accurately manage customer relationship and service response logistics along with tracking inventory and forecasting demands. Walmart was the first organization to implement the bar codes through which it was easy to analyze and collect information about storage levels within the organization. In addition, for strategizing global sourcing and outsourcing, the organization has proved itself to be a leader among all the other retailers (Heller 2017).

Logistics Management

Walmart is one of the biggest retailers in the world with 514.41 billion US dollars in the fiscal year 2019 (Chang and Hu 2020). The organization is considered as best for its practices for the supply chain management. These practices have enabled the organization to take a competitive advantage in the market along with enabling it to achieve retail industry leadership by focusing on increasing customer needs and operational efficiency (Barber 2018). Logistics and distribution management is the heart of the organization which keeps millions and billions of products moving to the customers every day. The organization has one of the fastest logistics infrastructure and responsive transportation system. Logistics infrastructure had played a role in a key competitive advantage for the organization. The distribution center of Walmart is provided with the service of more than 4000 company-owned trucks(LeCavalier 2016). The organization believes that the drivers should be dedicated to their work as well as committed to providing customer services with their full heart. That's why the company only hires those drivers that are well trained and have experience of driving 300000 accident miles without or no major violation of traffic (LeCavalier2016).

Integrated supply chain management

According to Pham (2018), the company has adopted computers in their supply chain management. This is where it uses a real-time stock management system, which has set reorder levels of certain goods. After a sale at the cashier, a code records the sale in the main database. When any goods get into the company's stores, it must go through the database section for entering in the system. With such kind of management, Walmart’s procurements managers at section levels and head office are able to manage their stocks effectively (Pham 2018).

Highly responsive supply chain

Nguyen (2017) stated that Walmart’s supply chain management is highly responsive. This means that the system changes with the changes in demand and customers’ needs. Although the information that the company has on the trend of business assists it to be slightly certain of the amount of product they should procure at a certain point, the demands of customers keep changing, thus changing the supply system is important. For example in December, the Christmas shop is busy than it is in January, the supply chain system is able to adjust to such changes. It can for instance seek assistance from the sports and fitness section to be able to cater to its increased demand in the Christmas shop (Nguyen 2017).

Supply Risks and Problems

According to Pham (2018), Walmart operates an in-house supply chain management with minimal outsourcing of services. For example in the maintenance of trucks, the company operates its own garage. This system of management creates a bigger burden to the management and sometimes failing the system. The system also requires the company to have ample capital to operate it's in house fleets since it has to buy modern Lorries to supply to final customers or to exporting ports. Road accidents and theft are some of the minor problems that face the companies supply chain management (Pham 2018).

Supply Risk management tactics

According to Shafiq, Johnson, Klassen and Awaysheh (2017), one of the strong points of Walmart’s supply chain system is the drivers. It has highly trained drivers who guarantee customers timely delivery. Control of traffic is computerized and every driver is aware of his/her responsibilities. The role of supplying millions of merchandise to customer's everyday lies on drivers. One of the ways of preventing loss is through ensuring trucks, drivers, and products on transits. This ensures that there is compensation in case of misfortune. When an international customer is procuring from the company, the company sells its goods at CIF (cost, insurance, and freight) value (Shafiq, Johnson, Klassen and Awaysheh 2017). This ensures that the goods have adequate insurance from the company stores to the port of destination. Local customers do not pay for insurance the company covers that for them. To control traffic, which could lead to inefficiency in the system, the company has developed an in-house computer traffic control. The system allocates different tracks to different departments according to the need that the department has expressed. It controls the lead-time and calls using loudspeakers (Shafiq, Johnson, Klassen and Awaysheh (2017).

Walmart Sustainable Procurement

According to Tan, Yan, Chen and Liu (2018), Wal-Mart has taken on the mantle of the environment not out of a sense of goodwill towards the environment, but because it has found that a lot of the things that will improve its environmental outcomes will also reduce its costs. The company hit upon this congruence at some point and has become creative at finding ways to reduce waste. The key equation is that waste = money has brought Wal-Mart to realize that there is a lot of waste within its system (Tan, Yan, Chen and Liu 2018). As a result, Wal-Mart works with suppliers to streamline their packaging less packaging tends to mean less waste diverted to landfills and less petroleum used in the creation of plastic, but it also means more product can fit onto a truckload, thereby improving the company's transportation efficiency. The result is a win-win situation for the environment and for Wal-Mart (and its customers). Thus, the approach that Wal-Mart takes towards environmental Stewardship tends to be efficiency-driven (Tan, Yan, Chen and Liu 2018).

According to Thakur and Muralidharan (2019), the company seldom if ever willingly engages in environmental efforts that would increase its costs, in part out of corporate philosophy but also because the company realizes that raising prices to make such accommodations would run counter to its business model and would be a problem for its customers. By seeking out these win-win situations, Wal-Mart is effectively using the principles of Sustainability to improve its bottom line. The company works with suppliers as well to improve efficiency throughout its entire supply chain (Thakur and Muralidharan 2019). Working with suppliers has always been part of Wal-Mart's strategy, using its bargaining to improve efficiency throughout the supply chain rather than just at its own operations. The result for Wal-Mart is that doing this with sustainability is just an extension of a strategy it already utilized. The key difference is that once Wal-Mart realized that there was a link between waste and money, it was able to look to sustainability and environmental science for ideas of things it could look at, and now Wal-Mart actively seeks out opportunities for this win-win situation (Thakur and Muralidharan 2019).

According to Barclay and Miller (2018), Seafood is an area where Wal-Mart saw a logical need for change Wild seafood is generally inefficient in terms of its production, and with many species is unethical because those species are threatened, at risk, or worse. The scarcity of fish due to overfishing was only creating an even worse situation with respect to the inefficiency of wild fish. One of the outcomes of this is that wild fish is becoming more expensive, which is unlikely to appeal to Wal-Mart customers. Fishing for wild seafood also represented 12% of total global oil use, a major drain on scarce energy resources chasing scarce fish (Barclay and Miller 2018). The natural response to this has been to increase the use of farmed seafood For Wal-Mart, farmed seafood represents both opportunity and challenge in that farmed seafood has lower nutritional value but it can be produced to a much higher level of efficiency than wild fishing could ever hope to achieve. Further. Wal-Mart was facing supply shortages as it increased its share of the seafood market in the United States. One of the responses of Wal-Mart to the fish problem was to utilize the MSC program, which was developed by Unilever and the World Wildlife Fund to label sustainable seafood products as such to discourage consumers from purchasing species deemed to be in danger of collapse. From this beginning, the networks were developed that would help Wal-Mart meet its challenges with respect to seafood (Barclay and Miller 2018).

Barendse, Basson, Petersen and Sink (2018) stated the company wanted to focus on sustainable wild-caught fish only, Wal-Mart also focused on an initiative called cluster farming that is used in Southeast Asia for shrimp farms, this region being a major source of the world's farmed shrimp supply. Cluster farming helps to enforce standards and provide a better livelihood for small-scale farmers Wal-Mart also supports initiatives to create marine reserves and public awareness of seafood-related issues. The MSC certification was important to Wal-Mart because it focuses on sustainable fisheries from boat to plate which means that there is control over the entire supply chain Walmart has always been in favor of control over the supply chain (Barendse, Basson, Petersen and Sink 2018). Wal-Mart taking greater control of the supply chain allowed for better control over the supply of fish on the market. This reduced the likelihood of fraud - the example in the case is of Russian illegally-caught salmon being passed off as Alaskan legal salmon with Wal-Mart level control of the supply chain it would be very difficult to do this. As it turned out there was a lot of legal fish in the market, and a lot of inefficiency in the supply chain that was adding to the cost and degrading the quality of the fish Wal-Mart was generally unaware of the extent of this and took steps with its suppliers to eliminate such waste. The result was a consolidation of the supply chain (Barendse, Basson, Petersen and Sink 2018).

Sustainability Measures development

Wal-Mart is also developing metrics for measuring sustainability. Typically, it is easier to make improvements when there are accurate measures. Thus, when Walmart develops such measures the supplier will have a better sense of what is current performance is, and what Wal-Mart needs that performance to be. According to Smith and Crawford (2019), the development of sustainability measures ends up being different for each different product, so it is important that measures are devised Wal-Mart doing so he is the cause of sustainability and helps Wal-Mart frame its own sustainability efforts. Wal-Mart also seeks to communicate with the public about its efforts (Smith and Crawford 2019). This has a few different effects. The first is that it helps Wal-Mart's brand image but this also creates a brand association with the public because the public starts to expend such performance from Wal-Mart. It is easier to convince suppliers to get on board with the program when it is dear that Wal-Mart has gone public with the strategy, is seeking the cooperation of suppliers and will be creating an expectation among customers with respect to environmental policy This is the company's way of holding everybody accountable by broadcasting is intentions through communication with the public (Smith and Crawford 2019).

According to Theron and Dowden (2017), Wal-Mart motivates its suppliers to reduce their environmental impacts in a few ways. The first is that they leverage the traditional Wal-Mart way of getting their suppliers to do anything which is to pressure them. Wal-Mart has tremendous bargaining power over its suppliers, many of whom are dependent on Wal-Mart for their business. The result is that when Wal-Mart asks its suppliers to do something, the suppliers tend to take that seriously. Wal-Mart does work with its suppliers as well because this presents a situation where both parties win. The result is that Wal-Mart helps its suppliers with ideas to improve their performance with respect to the environment, and both parties reap the benefits of improved efficiency (Theron and Dowden 2017).

According to Kaur and Singh (2019), Wal-Mart does not lean on suppliers to improve its environmental performance, the company also does a lot internally to improve its environmental record. The company has a small core sustainability team but opted against having a sustainability division or anything of that nature. In some instances, Wal-Mart has sought to make sustainability the responsibility of everybody at the company. The result is that all of the associates are expected to make their own contributions to sustainability initiatives. In some instances, Wal-Mart will measure its associate on their contributions, which has the effect of creating a higher degree of motivation among them to perform (Kaur and Singh 2019). Leveraging the associates is also intuitive, the associates know their stores better, and their operations better than most managers and certainly more than the people who are on the sustainability core team. The result of engaging the associates is that more and better ideas for environmental stewardship and efficiency have come about than would have been possible had the employees not been engaged.

Conclusion

It can be concluded that the report has critically examined the Procurement function of Walmart. This report has discussed the strategies to improve the procurement function of the organization by compensating external turbulences in the market. The sourcing and outsourcing strategy include technology, strategic vendor partnership, and cross-docking. Moreover, to improve the procurement function, the report has provided procurement strategies, supply risk tactics, and sustainable procurement. Walmart has the best logistic management that helps the organization to reduce the storage and transportation cost. Besides this, it was found that Walmart has to work on its sustainability procurement. It can involve its suppliers and manufacturers for sustainability procurement. The risk register and risk matrix is provided in the appendix which include ERP risk factors along with the risk description. To manage risk there are three things that an organization can do, which include accept the risk, mitigate the risk or transfer the risk. Risk response and risk resolution are also discussed in the risk matrix which is provided in the matrix.

References

Barber, D.A. 2018. Rule of Logistics: Walmart and the Architecture of Fullfillment by Jesse LeCavalier. Technology and Culture, 59(4), pp.995-997.

Barclay, K. and Miller, A. 2018. The sustainable seafood movement is a governance concert, with the audience playing a key role. Sustainability, 10(1), p.180.

Barendse, J., Basson, J., Petersen, S.L. and Sink, K.J. 2018. The sustainable seafood movement viewed as a maturing social-ecological issue using a South African case-study. Ocean & Coastal Management, 151, pp.178-192.

Chang, Y. and Hu, J. 2020. Analysis on the Mode of Multinational Retail Enterprises Entering Chinese Market—Take Walmart, Carrefour and Metro as Examples. Modern Economy, 11(01), p.17.

Cleary, S. and McLarney, C. 2019. Organizational Benefits of an Effective Vendor Management Strategy. IUP Journal of Supply Chain Management, 16(4).

Grangier, P., Gendreau, M.,Lehuédé, F. and Rousseau, L.M. 2017. A matheuristic based on large neighborhood search for the vehicle routing problem with cross-docking. Computers & Operations Research, 84, pp.116-126.

Heller, F. 2017. Technological innovation applied to walmart and tesco’s supply chain (Doctoral dissertation). Available at http://hdl.handle.net/10362/28327

Kaur, H. and Singh, S.P. 2019. Sustainable procurement and logistics for disaster resilient supply chain. Annals of Operations Research, 283(1), pp.309-354.

LeCavalier, J. 2016. The rule of logistics: Walmart and the architecture of fulfillment. United States: University of Minnesota Press.

Nguyen, T.T.H. 2017. Wal-Mart’s successfully integrated supply chain and the necessity of establishing the Triple-A supply chain in the 21st century. Journal of Economics & Management, 29, pp.102-117.

Pham, H. 2018. The impact of Blockchain Technology on the improvement of Food Supply Chain Management: Transparency and Traceability: A case study of Walmart and Atria. Available at http://urn.fi/URN:NBN:fi:amk-2018121020801

Shafiq, A., Johnson, P.F., Klassen, R.D. and Awaysheh, A. 2017. Exploring the implications of supply risk on sustainability performance. International Journal of Operations & Production Management.

Smith, N.C. and Crawford, R.J. 2019. Walmart: love, earth (A). In Managing Sustainable Business (pp. 243-267). Springer, Dordrecht.

Tan, B., Yan, J., Chen, S. and Liu, X. 2018. The impact of blockchain on food supply chain: the case of Walmart. In International Conference on Smart Blockchain (pp. 167-177). Springer, Cham.

Thakur, A.D. and Muralidharan, P. 2019. Sustainable Supply Chain Practices in Multinational Organizations. In Ethical and Sustainable Supply Chain Management in a Global Context (pp. 42-56). IGI Global.

Theron, C. and Dowden, M. 2017. Strategic Sustainable Procurement: Law and Best Practice for the Public and Private Sectors. London: Routledge.

Wells, J.R. and Ellsworth, G. 2016. The Inexorable Rise of Walmart? 1988—2016. Available at https://www.hbs.edu/faculty/Pages/item.aspx?num=50834

Appendix

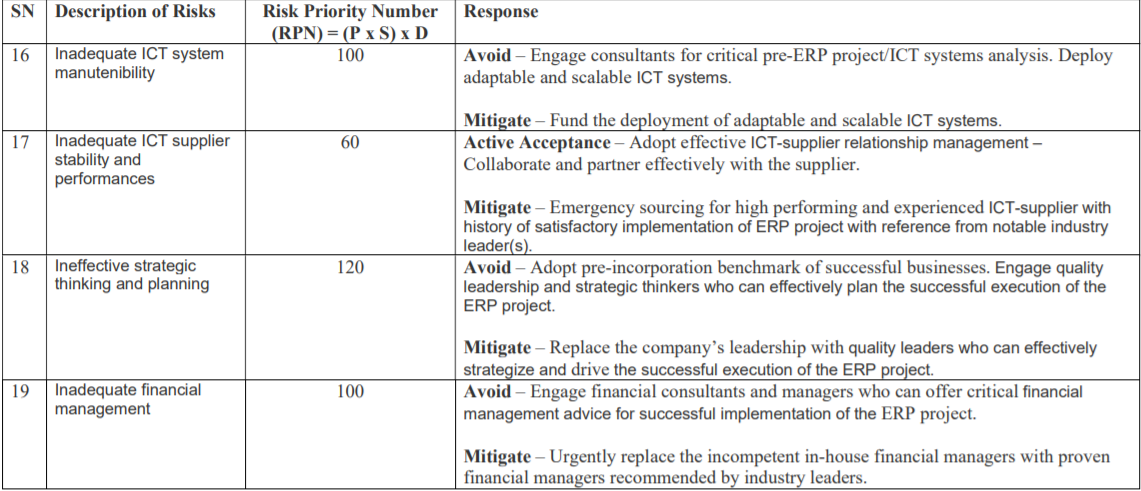

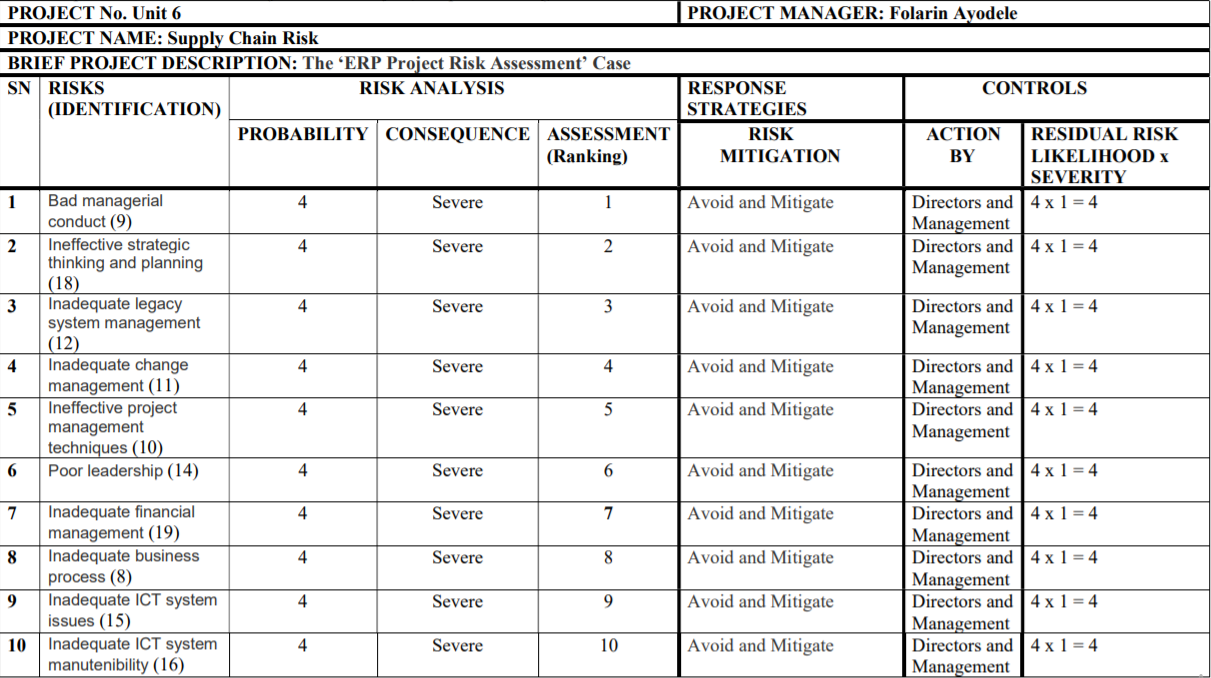

Risk Matrix and Risk Register

Risk Priority Number

Get It Done! Today

1,212,718Orders

4.9/5Rating

5,063Experts

Highlights

- 21 Step Quality Check

- 2000+ Ph.D Experts

- Live Expert Sessions

- Dedicated App

- Earn while you Learn with us

- Confidentiality Agreement

- Money Back Guarantee

- Customer Feedback

Just Pay for your Assignment

Turnitin Report

$10.00Proofreading and Editing

$9.00Per PageConsultation with Expert

$35.00Per HourLive Session 1-on-1

$40.00Per 30 min.Quality Check

$25.00Total

Free- Let's Start